Post-PEO Implementation

Post-PEO (period of extended operation) implementation includes the requirements and recommendations for aging management activities beyond the start of PEO. When a plant enters its PEO, their aging management programs (AMPs) become part of their current licensing basis (CLB), and therefore, the commitments to manage aging in the plant are applicable throughout the PEO. There are a number of requirements and recommendations that are applicable for a site that is officially entering into long-term operation.

Aging Management Coordinator (AMC)[edit]

The AMC is the single point of contact at a site who is generally knowledgeable of and responsible for on-going LR-related issues. For continuity, this person is generally established in the Pre-PEO period to coordinate and track to completion all of the activities at the site related to the LR. After a site enters into the PEO, the project group that performed the pre-PEO implementation is typically downsized, however there will continue to be on-going LR related activities that the AMC will continue to track.

Sites will likely have some additional inspections and/or commitments that need to be performed/fulfilled after the PEO starts. The AMC can be used to monitor these activities to ensure timely completion. Having access to the commitment closeout documentation from the Pre-PEO Implementation is helpful in answering questions that may arise in the PEO.

This individual can also be used to perform and/or coordinate the following reviews:

10 CFR 54.37(b) Reviews[edit]

These are annual or cycle-based reviews of site changes (CLB, modifications, etc.) to determine if additional SSCs need to be added to the scope of LR and age-managed. Additional guidance is found in US NRC RIS 07-016 Rev. 1, “Implementation of the Requirements of 10 CFR 54.37(b) for Holders of Renewed Licenses” and also in NEI report brief "Industry Best Practices for Performing 10 CFR 54.37(b) Reviews for ‘Newly Identified’ SSCs in Scope of License Renewal Aging Management”. The primary distinction within this process is between ‘Newly Identified’ components vs. ‘Newly Installed’ components.

- Newly installed: New components installed in the plant are assumed to be sufficient for any expected remaining life of the plant, and do not require 10 CFR 54 type aging management review. These components may be considered in-scope and subject to aging management in any subsequent LR submittals.

- Newly Identified: Components that were already installed in the plant at the time of the renewed license and not included in the scope of LR and aging management, but are subsequently identified as required to be in scope of LR and aging management due to recent modifications, CLB changes, or errors. These newly-identified components now need to be processed through Screening and AMR, and assigned to appropriate AMPs for aging management. These results would then be reported to the US NRC via formal docketed correspondence.

OE Reviews[edit]

Both plant-specific and industry age-related OE need to be reviewed to determine if changes are needed to applicable AMPs, or if new AMPs are needed (rare). NEI 14-13, Use of Industry Operating Experience for Age-Related Degradation and Aging Management Programs, helps provide the overall guidance for this effort. The use of the INPO OE database, via guidance contained in INPO 19-002, "Industry Reporting and Information System (IRIS): Reporting Requirements", can be used to assist in industry OE identification.

Sometimes these OE reviews may include reviews on new revisions of NUREG-1801 or -2191 (GALL) or newly issued US NRC LR-ISGs and SLR-ISGs, to determine if there might be any impact on existing AMPs or aging management activities. It should be noted that new requirements that may be found in newer revisions of the GALL are not mandatory, but can be evaluated by the site to determine if additional aging management activities may be warranted.

Effectiveness Reviews[edit]

Being that the aging management requirements are part of the sites CLB, it is important to routinely review on-going LR requirements to ensure they are being adequately maintained/implemented. NEI 14-12, Aging Management Program Effectiveness, provides guidance for this effort. NEI 14-12 recommends that every five years, all AMPs should be reviewed for effectiveness, and adjustments made as needed. These reviews can be coordinated by the AMC but should involve the individual [AMP Owners]. These reviews should look at OE to determine if adjustments might need to be made to better manage aging at the site, and to review program implementing documents to ensure that LR requirements are still in place.

Effective aging management of SSCs is a key element of the safe and reliable operation of nuclear power plants (NPPs). Hence, the licensee ensures that an effective aging management plan is implemented to ensure that the effects of aging will not prevent SSCs from being able to accomplish required safety functions throughout the lifetime of the facility (including its decommissioning).

International Implementation of Aging Management Programs[edit]

The IAEA, in some of its Specific Safety Requirements, SSR-2/1, “Safety of Nuclear Power Plants: Design” and SSR-2/2, “Safety of Nuclear Power Plants: Commissioning and Operation”, mentions that provisions should be made for monitoring, testing, sampling, and inspection to assess aging mechanisms predicted at the design stage and to help identify unanticipated behavior of the plant or degradation that might occur in service.

As it is established in IAEA’s SSG-48, each AMP should be developed using a structured methodology, to ensure a consistent approach in implementing aging management. Each program that is credited for aging management and used in evaluations for long term operation should be consistent with the attributes.

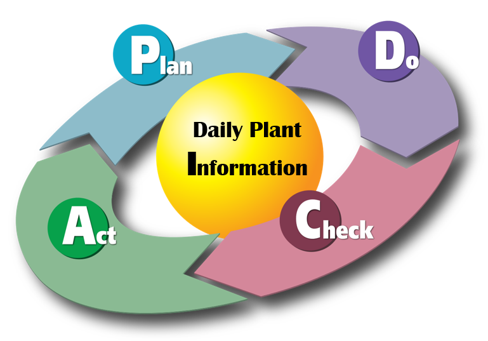

Once the AMPs have been defined, the Plan-Do-Check-Act (PDCA) cycle of the continuous improvement quality management tool “Plan-Do-Check-Act” should be started. The methodology of this four-step process could be transferred to the Aging Management Plan as follows:

- PLAN: Establishment of AMPs based on existing programs or through the development of new ones, in compliance with the attributes.

- DO: Carry out the preventive, predictive and/or monitoring activities necessary to be able to handle the aging effects associated with each AMP.

- CHECK: After the AMPs are developed, they should be implemented in a timely manner. To accomplish this aim, appropriate data, such as inspection results, should be collected and recorded for a defined period to provide evidence of compliance with the attributes of each AMP throughout the assessed period. This information is reviewed and quantified to provide a self-assessment of the degree of compliance with this AMP.

- ACT: Deficiencies that may be indicative of ineffectiveness associated with an AMP element would continue to be addressed using the corrective action program to increase the reliability of the AMPs. These actions will be scheduled to be carried out in an appropriate period.

Performance Indicators[edit]

Aligned with IAEA’s SSG-48, “Ageing Management and Development of a Programme for Long Term Operation of Nuclear Power Plants”, the effectiveness of aging management programs should be periodically reviewed to maintain plant safety and to ensure feedback and continuous improvements of AMPs. Hence, to evaluate the effectiveness of the AMPs, performance indicators (either qualitative or quantitative) should be developed and used by those in charge of aging management in the organization.

In IAEA’s SRS-82 “Ageing Management for NPPs: International Generic Ageing Lessons Learned (IGALL)”, it is stated that the effectiveness of aging management programs should be periodically assessed under the light of current knowledge and feedback from the program. Performance indicators representing the effectiveness of the aging management programs should be defined along with the development of the aging management programs and might be updated and adjusted as appropriate.

The effectiveness of AMPs is evaluated by performance indicators/criteria which can then be correlated to AMPs#10_Element_Approach AMP elements. For international long-term operation, what is referred to as "performance indicators", may be referred to as "performance criteria" in the US.

The IAEA’s SSG-48, provides some examples of performance indicators to assess the effectiveness of AMPs. These examples are listed below:

- Material condition with respect to acceptance criteria

- Trends of data relating to failure and degradation

- Percentage of recurrent aging driven failures and instances of degradation

- Status of compliance with inspection programs

- Newly discovered aging effects and degradation mechanisms

- Newly developed aging management programs

Examples of qualitative performance indicators to be applied as part of self-assessments have been described in the Quality Management attribute of some of the programs included in International Generic Ageing Lessons Learned (IGALL). As part of the process of implementing aging management programs, the outcomes of the AMP assessments are the essential inputs for the calculation of the defined performance indicators.

Regardless of whether the indicators defined for each program are qualitative or quantitative, an appropriate weighting criterion should be established for them that represents an overview of the status of each AMP. A numerical value or a color code establishes a “grade” for the effectiveness of each AMP, with the purpose of providing a basis for decisions on the type and timing of corrective actions, if needed.

Performance indicators and the related grading system provide an overview of the health of the plants’ AMPs and related SSCs. These indicators assist in identifying areas for improvement or highlighting aspects of the AMPs that are meeting or exceeding requirements and expectations.

LR Implementation Related Regulation[edit]

After PEO, the US NRC may perform additional inspections to ensure age-related degradation is being effectively managed.

- IP-71003 Post-Approval Site Inspection for License Renewal, Phase IV Inspection: this inspection typically takes place 5-10 years after entry into PEO. This is a LR-related inspection that specifically evaluates various aspects of aging management including: AMP effectiveness, corrective action response, commitment management, evaluation of OE, identification and incorporation of ‘newly identified’ SSCs per 10 CFR 54.37(b), and appropriate UFSAR incorporation.

- IP-71111.21N.04, “Age Related Degradation”: this inspection can review both passive and active age-related degradation (not necessarily LR-related items). This inspection is geared toward engineering performance and maintenance activities, to ensure they are being conducted as needed to incorporate age-related issues.

- US NRC inspections under the Regulatory Oversight Process : because the commitments made as part of the LRA become US NRC commitments, just like other commitments, the US NRC onsight inspectors and regional inspectors may inspect these commitments to confirm the commitments are being implemented properly.

LTO Related Industry Resources[edit]

- NEI's License Renewal Task Force (LRTF) Group is an industry working group that meets periodically to exchange information from recent audits and submittals, and to share site experiences and issues, and can be a great resource for the AMC.

Record of Revisions[edit]

| Number | Date | Description of Changes |

|---|---|---|

| 0 | 6/11/2024 | Initial version |