Periodic Safety Reviews (PSRs)

The main measures to guarantee safety of a Nuclear Power Plant (NPP) must be ensured by routine operational reviews of the plant and other special assessments following safety-relevant events.

Some countries have initiated systematic, comprehensive, and integrated safety reviews, named periodic safety review (PSR), to assess the cumulative effects of plant aging, plant modifications, operating experience, technical developments, and siting aspects.

Other countries, like the U.S., have on-going comprehensive reviews that don’t require periodic safety reviews. The US NRC has done a comprehensive comparison of the PSR practices with the US practices to show how the on-going comprehensive review practices compare with the PSR practices. In summary, the objectives of the PSR process are well served by the U.S. regulatory process. The US NRC agreed with the three main goals of the PSR:

- To confirm that the plant is as safe as originally intended,

- To determine if there are any SSCs that could limit the life of the plant in the foreseeable future, and

- To compare the plant against modern safety standards and identify where improvements would be beneficial at justifiable cost

The US NRC concluded that the current U.S. regulatory process ensures these goals are met. The U.S. regulatory structure ensures through its licensing process that plants are thoroughly and comprehensively reviewed prior to allowing operation to begin, during operation, and prior to allowing extended periods of operation. The full details of the US NRC report are available in ADAMS document ML112510453.

According to the IAEA Specific Safety Guide Nº 25 (SSG-25), “Periodic Safety Review for Nuclear Power Plants ” a PSR includes an assessment of plant design and operation against applicable current safety standards and operating practices and has the objective of ensuring a high level of safety throughout the plant’s operating lifetime. It is complementary to the routine and special safety reviews conducted at nuclear power plants and does not replace them.

The International Atomic Energy Agency (IAEA) defines PSR as a comprehensive safety review of all important aspects of safety, conducted at regular periods, typically every ten years. In addition, a PSR could support the decision-making process for license renewal or long-term operation, or for restarting a nuclear power plant after an extended shutdown.

IAEA, SSG-25 provides recommendations and guidance on the development of a PSR for an existing nuclear power plant. IAEA Safety Report Series Nº 121 (SRS-121), “Use of Periodic Safety Review for Long Term Operation of Nuclear Power Plants” mainly describes criteria for using PSR results to support long term operation (LTO) justification and details good practices for LTO and PSR programs at NPPs with examples from Member States.

In many countries, the PSR is required by the regulatory system. However, the scope and content of the PSR, as well as the way in which it is carried out, vary according to the regulations of each country. The PSR provides a means to regulate the safety of a plant’s long-term operation. It can also address requests from licensees for authorization to continue operating plants beyond an established license term or for an additional period established by a safety assessment.

In this sense, the PSR provides an effective way to obtain an overview of the actual safety of the plant and the quality of the safety documentation. It also identifies reasonable and practical modifications to ensure or improve safety to an appropriately high level during continued operation. To do this, the PSR needs to identify any life-limiting features of the plant to determine if there is a need to modify, refurbish or replace certain structure, systems and components (SSCs) to extend the operational lifetime of a NPP.

According to SSG-25 , the objective of PSR is to determine through a comprehensive assessment the following aspects:

- The adequacy and effectiveness of the arrangements and SSCs are in place to ensure the safety of the plant until the next PSR or until the end of the planned operation.

- The degree of compliance of the plant with national safety standards and operating practices and/or national and/or international safety standards and operating practices in force.

- Safety improvements and deadlines for their implementation.

- The extent to which the safety documentation, including the licensing basis, is still valid.

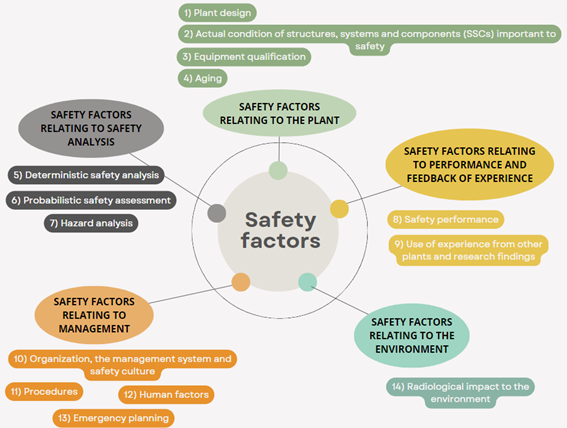

To address the complete safety assessment of the NPP, the PSR can be divided into 14 sections which cover the 14 safety factors important for the safety of an operating NPP.

The 14 safety factors recommended in [SSG-25 are as follows :

- Safety factors relating to the plant

- (1) Plant design

- (2) Actual condition of structure, systems and components (SSCs) important to safety

- (3) Equipment qualification

- (4) Aging

- Safety factors relating to safety analysis

- (5) Deterministic safety analysis

- (6) Probabilistic safety assessment

- (7) Hazard analysis

- Safety factors relating to performance and feedback of experience

- (8) Safety performance

- (9) Use of experience from other plants and research findings

- Safety factors relating to management

- (10) Organization, the management system and safety culture

- (11) Procedure

- (12) Human factors

- (13) Emergency planning

- Safety factors relating to the environment

- (14) Radiological impact on the environment

During the review of each safety factor, positive and negative findings should be identified, and these are defined in SSG-25 below:

- Positive findings or Strengths: Where current practice is equivalent to good practices as established in current codes and standards, etc.

- Negative findings or Deviations: Where current practices are not of a standard equivalent to current codes and standards or industry practices, or do not meet the current licensing basis, or are inconsistent with operational documentation for the plant or operating procedures.

PSR Process[edit]

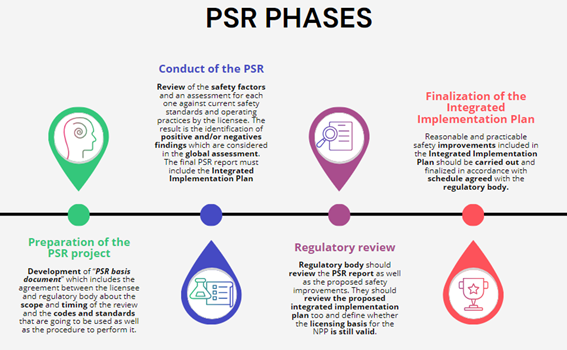

The entire process related to the PSR should be divided into the following four phases.

Periodic Safety Review's Safety Factors[edit]

The important aspects of the safety of an operating nuclear power plant assessed in a PSR are named safety factors, which are used to divide the PSR and to address it more easily. The review of the safety factors will identify positive (strength) and negative (deviation) findings that should be documented in the safety factor review report.

The Safety Guide SSG-25 describes the objective, scope, and methodology of each of the factors for conducting the assessment of each factor. Each of the factors is described below, and those related to component aging are developed in depth. Each country can select its safety factors for its PSR, and not necessarily all of the following safety factors are reported in the PSR.

Use of Periodic Safety Review for Long Term Operation[edit]

The main goal of the PSR is to drive the plant’s continuous safety improvements. As the usual interval between PSRs is ten years, it means that the third or fourth PSR is normally used to assess safety factors related to operation beyond the originally intended or licensed lifetime, commonly called "long-term operation" (LTO).

As mentioned in the Overview – Periodic Safety Review, IAEA Safety Report Series Nº 121 (SRS-121), “Use of Periodic Safety Review for Long Term Operation of Nuclear Power Plants” covers the scope of the LTO assessment, methods, and criteria applicable to support decision making under the PSR and LTO programs.

The aims of this reference are to verify whether the facility adequately meets current standards and practices, whether the (updated) licensing basis will be valid throughout the intended operating period, arrangements are in place to ensure that the safe operation is maintained over the LTO period, and if the improvements to be implemented deal with the identified safety issues.

In cases where the PSR is used as input to decision making for LTO, the documentation needs to clearly define the scope of the assessments related to LTO that are carried out in the PSR. The main differences between a standard PSR and a PSR for LTO are described in SRS-121. However, related to the current status of the components, the PSR for LTO requires a review of the aging management and its alignment with IAEA Safety Standards Series Nº 48 (SSG-48), “Ageing Management and Development of a Programme for Long Term Operation of Nuclear Power Plant”, especially regarding the scope, as pointed out in paragraph 5.16 of SSG-48.

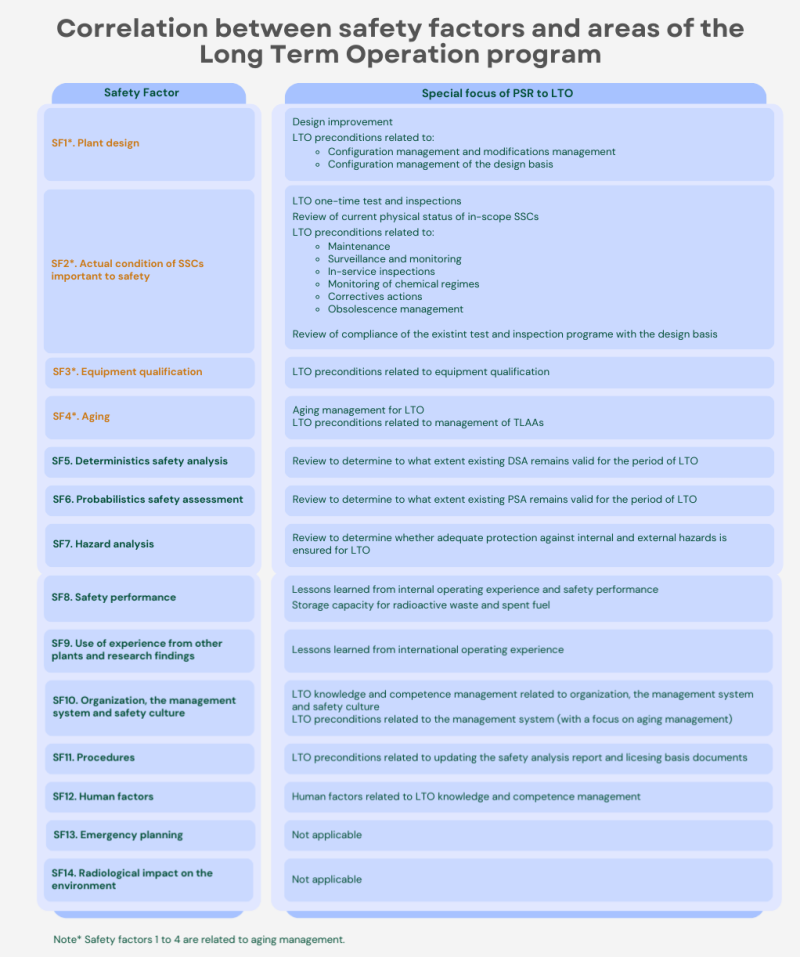

In the PSR for LTO, it is necessary to broaden the scope of the safety factors related to aging to include an assessment of time limitation assumptions and aging effects assessments. In the review, greater importance is given to the aging effects, degradation mechanisms, AMPs, and obsolescence, so the most relevant safety factors for justification of LTO are those related to the plant:

Additional areas within other safety factors that can support justification of LTO are the capacity for long term storage of spent fuel and radioactive waste, environmental monitoring and authorized discharges, plant safety performance and review of non-aging related processes, such as those for corrective actions and operating experience.

As mentioned in Overview - Periodic Safety Review, the entire process of a PSR consists of four phases. In PSR for LTO, the scope of the review of the safety factors, which is described in the PSR basis document, can be adopted to support an assessment of the feasibility of LTO.

In the previous section, Periodic Safety Review's Safety Factors, the main purpose of the safety factors review is described. In addition, for those more related for justification of LTO, the scope of the review and the corresponding methodology to carry out the review of each one of them is included. On the other hand, sections 2.3.2.2 - 2.3.2.5 of SRS-121 clarify the methodology for reviewing those safety factors related to plants when considering LTO.

It should be noted that it is recognized by SRS-121 that the PSR and LTO programs could be coordinated to avoid repetitive, recurrent, or overlapping activities, and to ensure that no major activities are omitted. In those areas where significant work has been completed in the LTO program, the PSR of those areas could be limited to scheduled reviews. The safety factors where this opportunity exists are safety factor 2 (actual status of SSCs important to safety), safety factor 3 (equipment qualification), and safety factor 4 (aging). Section 3 of SRS-121 details synergies between both the PSR and LTO programs, which should be taken into account in the review of the PSR safety factors for LTO.

The following table, included in SRS-121 , points out the correlation between safety factors and areas of the Long-Term Operation program.

Once all the safety factors have been reviewed, the global assessment considers all findings and proposed safety improvements based on the safety reviews and interfaces among them. Section 4 of SRS-121 describes, in depth, how to address deviations identified through the review of safety factors and their safety significance and provides recommendations for analyzing interfaces, gaps, and overlaps among safety factors and for considering the combined effects of findings. Moreover, it covers the consideration of the assessment of defense in depth as well as the criteria and methodology to define reasonably practicable safety improvements which will then be in included in the development of the Integrated Implementation Plan.

As described in the third phase of the PSR project, the regulatory body should review the PSR report elaborated by the licensee as well as the proposed safety improvements included in the Integrated Implementation Plan to define whether the licensing basis for the NPP is still valid.

Subsequently, the Integrated Implementation Plan must be updated to respond to the commitments identified, listed, and agreed upon with the regulatory body as a result of the assessment included in LTO and PSR programs.

Annex I of SRS-121 summarizes the practices that the following IAEA Member States employ when using PSR in support of LTO.

- United Kingdom

- Netherland

- Canada

- Spain

IAEA References[edit]

- IAEA Specific Safety Guide Nº 25 (SSG-25), “Periodic Safety Review for Nuclear Power Plants"

- IAEA Safety Report Series Nº 121 (SRS-121), “Use of Periodic Safety Review for Long Term Operation of Nuclear Power Plants”

- IAEA Safety Standards Series Nº 48 (SSG-48), “Ageing Management and Development of a Programme for Long Term Operation of Nuclear Power Plant”

Record of Revisions[edit]

| Number | Date | Description of Changes |

|---|---|---|

| 0 | 6/11/2024 | Initial version |