U.S. NRC License Renewal Inspections

IP-71002 License Renewal Inspections[edit]

The US NRC IP-71002, “License Renewal Inspection” site inspections are assessments of an applicant’s implementation of and compliance with 10 CFR Part 54 requirements. The inspection typically occurs during the US NRC review of the LRA or SLRA following the US NRC audits and verifies the implementation of (or readiness to implement) license renewal activities. The three inspections are as follows:

Scoping and Screening Inspection: This inspection verifies on a sampling basis, through onsite review and walkdown of selected areas of the plant that there is reasonable assurance that the applicant has adequately documented all the identified passive and long-lived structures systems, and components (SSCs) requiring an aging management review (AMR).

Aging Management Program Inspection: This inspection verifies, through review of supporting documents and a walkdown of select systems, that the effects of aging can be adequately managed in the period of extended operation (PEO).

Annual Update/Open Item Inspection: These inspections verify any changes made by the applicant were incorporated into an annual license renewal (LR) update, verify any issues from previous inspections were resolved, and verify committed tasks are on track to be completed prior to and during the period of extended operation. Additional inspections to review open items will be conducted at the option of the Regional Administrator.

US NRC IP-71003 Post-Approval Site Inspections for License Renewal[edit]

US NRC post-approval site inspections are part of the license renewal inspection program after the renewed license has been issued, which the US NRC has implemented to verify continued compliance with 10 CFR Part 50 and implementation of LR commitments.

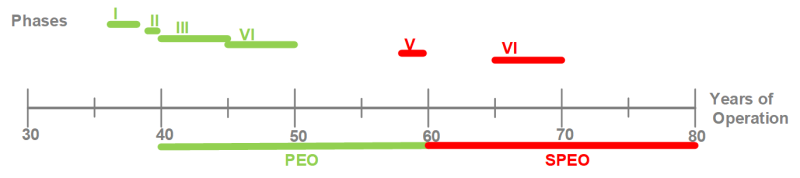

Post-approval site inspections are conducted in accordance with US NRC procedure IP-71003. The IP-71003 review is an inspection, during which, the US NRC staff compares the licensee’s activities against standards (commitments) or requirements (license conditions). This provides reasonable assurance that the effects of aging will be managed through the period(s) of extended operation (PEO), such that the plant’s SSCs will continue to perform their intended functions in accordance with the current licensing basis (CLB). IP-71003 inspections are conducted in four phases following initial approval for plant life extension and an additional two phases following approval for subsequent life extension.

Inspection for Initial and Subsequent License Renewal: Phase I, II, III, IV, V, and VI[edit]

Initial License Renewal (40-60 Years)[edit]

Phase I[edit]

This portion of the inspection is likely to occur 1-2 refueling outages before the licensee enters the PEO. The inspectors will observe the implementation of select aging management programs (AMPs) and activities described in the license conditions, updated final safety analysis report (UFSAR), time-limited aging analyses (TLAAs) and regulatory commitments, as well as any testing or visual inspections of SSCs which are only accessible at reduced power levels. Those SSCs may be located inside the containment and other high radiation areas. The Phase I inspection may occur at each unit of a multi-unit site.

Phase II[edit]

This portion of the inspection is likely to occur three months to a year prior to the licensee entering the PEO depending on the licensee’s implementation schedule of outages and license renewal activities. The Phase II inspection is intended to be a one-time team inspection per site. However, for multi-unit sites, subsequent Phase II inspections may be conducted, as deemed necessary by regional management. Subsequent Phase II inspections at multi-unit sites may not require the same level of effort as the Phase II inspection for the first unit. The inspectors will assess the adequacy and effectiveness of the implementation and/or completion of the programs and activities described in the regulatory commitments, UFSAR supplement program descriptions, TLAAs, and license conditions, as well as evaluate the need for additional inspections under inspection procedure (IP) 71003, or as part of the reactor oversight program (ROP).

Phase III[edit]

This portion of the inspection can occur within the first five years of the PEO. This inspection is optional and is implemented when deemed necessary by the Phase II inspection team, based on the results of the Phase I and II inspections. The Phase III inspection reviews the implementation of license conditions, regulatory commitments, TLAAs, and AMPs against the implementation schedules that extend into the PEO. Additionally, Phase III may be implemented to review corrective actions for issues of concern identified during Phase I and II inspections.

Phase IV[edit]

This portion of the inspection is likely to occur 5-10 years into the PEO to verify the licensee is managing aging effects in accordance with the AMPs described in the UFSAR. Phase IV is intended to be a one-time inspection per site. However, the Phase IV inspection can be performed on each unit of a multi-unit site as deemed necessary. Furthermore, the inspection may be repeated if deemed necessary based on the outcome of the inspection (for example, 3 years later to determine if the licensee has corrected any identified issues).

During the Phase IV inspection, inspectors are expected to:

- Review approximately six samples of a licensee’s implementation of aging management programs (AMPs), to determine AMP effectiveness. The actions described in the license renewal application (LRA) AMPs and aging management review (AMR) items are implemented at the site in changes to plant-specific procedures (e.g., inspection requirements for lighting) and preventive maintenance activities (PMs), as required. The inspectors should consider a review of the enhanced, new, or plant-specific AMPs.

- Perform a review of corrective action program (CAP) documents to determine if age-related degradation has been identified and properly managed or corrected, as part of their AMP samples. The expectation is that the AMPs have been updated based on operating experience (OE) and other relevant information.

During the Phase VI inspection, inspectors will:

- Verify the licensee is implementing the AMP elements consistent with the revised licensing basis as implemented upon entry into the subsequent PEO to ensure the SSCs have maintained their ability to perform their intended function.

- Verify that the licensee adequately evaluated plant-specific and industry OE, and when applicable, incorporated appropriate changes to the methods of managing aging effects for items subject to AMR, in accordance with the UFSAR description on the use of OE (as applicable).

- Verify age-related degradation is identified and corrected.

- Verify that the licensee identified, evaluated, and incorporated “newly identified” SSCs into the renewed license in accordance with 10 CFR 54.37(b).

- Since the inspections in Phase V, verify that the licensee adequately evaluated, and reported when necessary, changes to regulatory commitments from the SE for SLR in accordance with the Nuclear Energy Institute’s (NEI), NEI 99-04 , "Guidelines for Managing NRC Commitment Changes" (ADAMS Accession No. ML003680088), as endorsed by RIS 00-017, “Managing Regulatory Commitments Made by Power Reactor Licensees to the NRC Staff” (ADAMS Accession No. ML003741774); changes to AMPs, TLAAs and other SLR activities incorporated as part of the UFSAR supplement in accordance with 10 CFR 50.59; and submitted license amendment requests in accordance with 10 CFR 50.90 for changes to license conditions that were added as part of the renewed operating license.

- Verify the UFSAR supplement description matches the AMP or TLAA being implemented and that changes, necessitated by the inclusion of “newly identified” SSCs, were included in the UFSAR supplement. If the licensee has not submitted a UFSAR supplement update since implementing the AMP or TLAA, review the planned UFSAR supplement changes and verify that they are included in an appropriate tracking system (e.g., a CAP ).

Subsequent License Renewal[edit]

Phase V[edit]

This inspection is likely to occur 3-12 months or one outage prior to the subsequent period of extended operation (SPEO). This inspection is intended to be a one-time team inspection per site; however, for multi-unit sites, subsequent inspections may be conducted, as deemed necessary. During the Phase V inspection, inspectors will:

- Verify, on a sampling basis, that the licensee adequately completed the actions necessary to comply with the license conditions and commitments for SLR, and adequately implemented the AMPs and TLAAs as described in the safety evaluation (SE) for SLR.

- Verify that the licensee adequately evaluated, and reported when necessary, changes to regulatory commitments from the SE for SLR in accordance with the Nuclear Energy Institute’s (NEI), NEI 99-04 , "Guidelines for Managing NRC Commitment Changes" (ADAMS Accession No. ML003680088), as endorsed by RIS 00-017, “Managing Regulatory Commitments Made by Power Reactor Licensees to the NRC Staff” (ADAMS Accession No. ML003741774); changes to AMPs, TLAAs and other SLR activities incorporated as part of the UFSAR supplement in accordance with 10 CFR 50.59; and submitted license amendment requests in accordance with 10 CFR 50.90 for changes to license conditions that were added as part of the renewed operating license.

- The inspection verifies that the licensee identified, evaluated, and incorporated “newly identified” SSCs into the renewed license in accordance with 10 CFR 54.37(b), as well as evaluate the need for additional inspections in Phase VI or as part of the ROP.

Phase VI[edit]

This inspection is likely to occur 5-10 years into the SPEO. Phase VI accomplished the same objective as Phase IV and shares the same inspection requirements. Phase VI is intended to be a one-time inspection per site. However, the Phase VI inspection can be performed on each unit of a multi-unit site as deemed necessary by regional management.

During the Phase VI inspection, inspectors are expected to:

Review approximately six samples of a licensee's implementation of AMPs, to determine AMP effectiveness and perform a review of CAP documents to determine if age-related degradation has been identified and properly managed or corrected, as part of the AMP samples. The expectation is that the AMPs have been updated based on OE and other relevant information.

IP-71013 Site Inspection for Plants With a Timely Renewal Application[edit]

For applicants whose renewed operating license has not been approved before the plant enters the period of extended operation, IP 71003 would not be applicable. This is a very rare situation, so this process is not common. IP 71013 , “Site Inspection for Plants With a Timely Renewal Application,” was developed to allow US NRC inspection of license renewal programs for these applicants. A three-phrase approach to completing the inspections is recommended. The timely renewal (TR) Phases are as follows:

- TR Phase 1 observes the implementation of select AMPs and activities described in proposed license conditions, the UFSAR supplement, AMPs, TLAAs, and other regulatory commitments proposed during the license renewal review, as well as any testing, or visual inspections of SSCs which are only accessible at reduced power levels.

- TR Phase 2 is a one-time major team inspection per site.

- TR Phase 3 occurs after issuance of the renewed license and after the licensee enters the PEO. This Phase of the inspection reviews the implementation of approved license conditions, regulatory commitments, TLAAs, and AMPs.

If, during the planning, execution, or documentation of this procedure, the US NRC determines the operating license will not be renewed, inspection efforts should cease. Upon issuance of the renewed license and completion of TR Phase III, subsequent inspection efforts should shift to the corresponding portion of IP 71003.

Preparing for Post-Approval Site Inspections[edit]

There are several aspects to preparation for post-approval site inspections. Some tasks for nuclear power plants include but are not limited to:

- Assembling AMP and TLAA “notebooks”

- Assigning AMP owners and conducting training

- Conducting “challenge boards” to ensure AMP owners and site personnel have a sufficient level of knowledge to implement license renewal commitments

- Performing OE reviews

- Revision of LR basis documents and procedure updates

Related Non-License Renewal US NRC Inspections[edit]

IP-71111.21N.04 Age-Related Degradation[edit]

The objective of this US NRC site inspection is to verity that engineering performance and maintenance activities to address age-related degradation for structures and components (SSCs) are being conducted in a manner that provides reasonable assurance of the safe operation of the plant. This inspection will also verify that age-related degradation for plant SSCs are appropriately identified, addressed, and corrected.

This inspection is not a license renewal inspection; however, the scope of the inspection does include components managed for license renewal. The IP-71111.21N.04 inspection occurs on a quadrennial frequency.

International Approach[edit]

It is the task of the regulatory body to provide for safety oversight of facilities throughout the operational lifetime of the facilities. For that purpose, the regulatory body shall establish or adopt regulations and guides to specify the principles, requirements and associated criteria for safety upon which its regulatory judgements, decisions and actions are based. That review and assessment of information shall be performed prior to authorization for extended operation and again over the lifetime of the facility, or the duration of the activity to determine whether the requirements and conditions for the authorization have been met. Furthermore, for the LTO period, the regulatory body should oversee that the safety of the nuclear power plant (NPP) will be maintained throughout the period of long-term operation in accordance with current safety standards and national regulatory requirements.

The IAEA guidelines or standards specify that the plant design considers aging of the structures, systems and components (SSCs), and that an effective aging management program (AMP) be implemented during operation, to ensure that the safety functions of SSCs are fulfilled over the entire operating lifetime of the plant. In relation to long-term operation (LTO), IAEA specifies that, where applicable, a comprehensive program for LTO be established and implemented based on safety assessments, with proper consideration for the aging of SSCs.

Thus, in order to carry out such safety oversight of facilities throughout their operational lifetime, the IAEA has published the safety report SRS-109, “Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power Plants” which provides technical and practical information based on the existing regulatory approaches and practices of Member States about oversight of aging management and preparedness for safe LTO of NPPs.

- Sections 2 through 7 outline the legal framework, as well as the requirements and guidelines that are available in the different Member States to conduct the review of aging management for LTO.

- Section 8 describes the practices applied for the self-preparation of the regulatory body for oversight of LTO.

- Section 9 contains guidance for regulators on reviewing the scope determination, AMR, AMP development and implementation, TLAA revalidation and documentation and follow-up of findings.

- Section 10 describes the regulatory practices followed in the LTO period.

In addition, GSG 13, “Functions and Processes of the Regulatory Body for Safety”, describes recommendations for subjects of review and assessment by the regulatory body on equipment qualification and management of aging.

The LTO implementation phase follows the issuance of a formal agreement or authorization for continued operation (depending on the licensing process of the member state). License conditions or corrective actions from the licensing process, as well as commitments from the operating organization, are usually included in a plant's corrective action program, which typically, also covers other licensee activities associated with LTO. The role of the regulatory body is to review the completeness of the action plans and to check the adequacy of the proposed schedules for compliance with the corrective actions. The licensee submits the status of the action plans to the regulatory body according to an established schedule. Fulfillment of corrective actions is verified through oversight, which is carried out by the regulatory body.

Similar to the rest of the aspects related to ageing management, the regulatory body of each country establishes its own methodology, scope and even inspection frequency to perform oversight of the facilities in that country. The following is a broad description of the methodology followed by the Spanish regulatory body.

Example of regulatory approach in Spain[edit]

The Spanish regulator has a procedure in place which outlines the strategy to be followed in the oversight of aging management in Spanish NPPs throughout their design life and possible long-term operation period, as well as during the license renewal process required to achieve a life extension of a facility.

Regulatory inspections are performed every two years during the different phases of the plant's life including LTO and their purpose is to verify:

- The facility can reach the original design life without detriment to safety, avoiding unplanned degradation of the structures, systems and components of the facility (SSCs) important for safety.

- An aging control, monitoring, and mitigation program has been established during the original design life, which allows reaching the technical-economic life defined in the plant's strategy.

- The aging management approach established by the facility for LTO reasonably guarantees the functionality of the safety-relevant SSCs during the extended lifetime period.

- During the LTO period, the necessary aging management activities are performed in order to reasonably guarantee the surveillance, control, and mitigation of the aging effects of the safety-relevant SSCs; avoiding their unexpected degradation and, therefore, a safety detriment.

Based on the above objectives, oversight is conducted during the different phases of a NPP, and in each of them, the regulatory body pursues specific aims.

Inspections during the design life of NPP[edit]

Depending upon the manner in which NPP documentation is organized, one to two systems of the plant will be selected and aspects of mechanical, electrical, and/or civil will be verified in a multidisciplinary method.

As the aging management plan implementation phase progresses, oversight will include a broad sample of aging impact assessment and maintenance activities to be inspected. In the final stages, the inspection will be focused on the verifications related to the real implementation of the aging management plan.

To address these inspections, between two and three inspectors are required.

Inspections during the license renewal process[edit]

As a guideline, between four and eight inspections may be necessary, and these oversight inspections will evaluate the Integrated Plan for the Evaluation and Management of Aging (PIEGE). Scope and screening of SSCs, AMR, AMPs, and TLAAs will be assessed.

The inspections will focus on:

- The general aspects of the methodology used to conduct the review, and

- The assessment of certain systems or structures of the facility; chosen according to their safety relevance, and their representativeness within the category of systems to which they belong.

- This sample selection can vary on a case by case basis. The total selection of systems and structures to be inspected should be between 15% and 20% of the total systems and structures within the scope of license renewal.

To address these inspections, between 3 and 6 inspectors are required.

Inspections during the Long-Term Operation of an NPP[edit]

Every two years, activities carried out by the facility related to the aging management plan for LTO will be reviewed. As part of the oversight inspection, the following will be reviewed:

- - The set of activities linked to three or four AMPs

- - Analyses of internal and external OE

- - One or more relevant design modifications that have occurred at the facility since the last inspection, to verify the licensees’ analyses and to determine if new components need to be included within the scope of LR

- - Administrative updates to aging management documentation and processes to reflect changes resulting from the items listed above (e.g., AMP scope updates, implementing procedure updates, etc.)

To address these inspections, between 2 and 3 inspectors are required.

Matrix of Inspections[edit]

The table below depicts the various LTO aspects assessed during regulatory inspections and the phase of operation in which the assessment is performed. A brief description of each aspect is included below the table.

| Inspections during the design life of NPP | Inspections during the license renewal process | Inspections during LTO | |

|---|---|---|---|

| Documentation related to the Aging Management Plan | X | X | |

| Documentation related to the license renewal process | X | ||

| Organization of the licensee | X | X | |

| Recording of information | X | X | |

| Follow-up of commitments | X | X | |

| Scope and screening | X | X | X |

| Aging Management Review (AMR) | X | X | X |

| Aging Management Programs (AMPs) | X | X | |

| Follow-up of improvement proposals | X | X | |

| Monitoring of design modifications and equipment replacements related to aging management | X | X | |

| Follow-up of support document revisions | X | X | |

| Time-Limited Aging Analyses (TLAAs) | X | ||

| Identification and resolution of Generic Safety Issues (GSI) related to aging management | X | X | X |

| Obsolescence management | X | X |

Documentation Related to the Aging Management Plan[edit]

Annual documentation created by the licensee which contains basic information about the process methodology of the different phases of aging management plan, as well as about the aging management strategy and activities carried out during the period.

Documentation Related to the License Renewal Process[edit]

The facility's Integrated Plan for the Evaluation and Management of Aging (PIEGE) which contains a consolidated analysis of all aspects related to aging management (scope and screening, AMR, AMPs and TLAAs).

Organization of the Licensee[edit]

Definition of the facility's organization (group or committee) for aging management. The membership and leadership, functions and activities to be developed, frequency of meetings and topics dealt with, and decisions adopted will be discussed.

Recording of Information[edit]

A data acquisition and recording system should be available to support the AMPs.

Follow-up of Commitments[edit]

The degree of progress or effective resolution of the commitments adopted by the licensee in past inspections. If authorization is granted for long-term operation, implementation of improvement, corrective, or compensatory actions will be needed. In this case, the inspection will focus on verifying the degree of progress of these actions and compliance with the established deadlines.

Scope and Screening[edit]

Describes the methodology used by the licensee to determine the scope and selection of the SSCs to be submitted to the aging management review process (AMR), and contains the subsequent results of the scoping and screening process.

Aging Management Review (AMR)[edit]

Based on the result of the previous phase, the purpose of the inspection in this point will be to ensure that the aging effects of the SSCs are adequately managed, to maintain the corresponding functions throughout the extended lifetime.

Aging Management Programs (AMPs)[edit]

Several AMPs are selected, and the results obtained from them will be provided for a period as convenient for one or several components in scope. Special attention will be given to those AMPs that are specific to a NPP, that raise exceptions or that are related to TLAAs. The direct observation of an activity related to an AMP will also be subject to inspection, which will allow the verification of all aspects related to the AMP and enables the direct assessment of the status of the SCCs in scope.

Follow-up of Improvement Proposals[edit]

Verification of the licensee's adequate management of the process to resolve improvement proposals. Some of them will be selected and the steps established for their resolution will be analyzed.

Monitoring of Design Modifications and Equipment Replacements Related to Aging Management[edit]

Review of the methodology developed by licensee to analyze the impact of design modifications and component replacements with aging management at regular intervals, and to proceed with the necessary updates of the aging management strategy.

Follow-up of Support Document Revisions[edit]

Updated list of supporting documents will be requested, and the regulator will analyze the reasons that originated the new revisions, as well as the content and the results.

Time-Limited Aging Analyses (TLAAs)[edit]

Verification of the appropriate methodology which ensures the identification of all TLAAs according to the current licensing basis (CLB), as well as the analysis and resolution of each one of them.

Identification and Resolution of Generic Safety Issues (GSI) Related to Aging Management[edit]

Methodology for the periodic identification of GSIs related to aging effects and applicable to SSCs in scope will be verified. In addition, for oversight related to the license renewal process, it will be verified that the licensee has reevaluated the GSIs previously identified and have identified those that are TLAAs.

Obsolescence Management[edit]

Identification and evaluation of the obsolescence management program, as well as the strategy defined to resolve the different kinds of obsolescence cases. The effectiveness of the program will also be evaluated, as well as the continuous improvement actions.

Record of Revisions[edit]

| Number | Date | Description of Changes |

|---|---|---|

| 0 | 6/11/2024 | Initial version |