Time Limited Aging Analyses (TLAA)

Revision 0

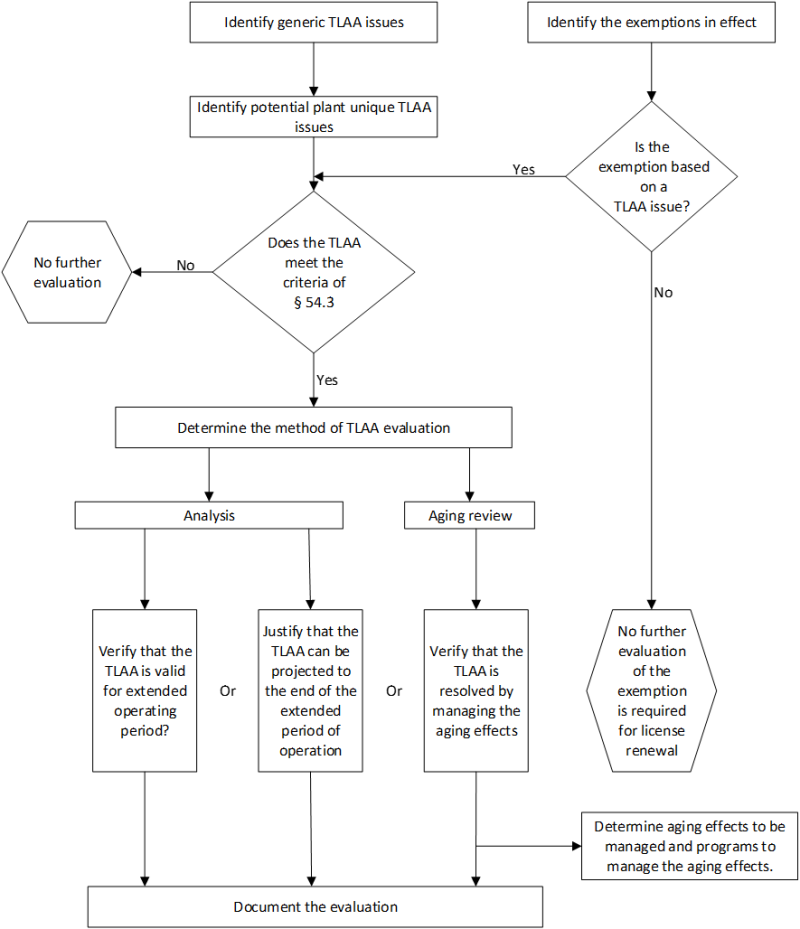

The License Renewal Rule, 10 CFR 54 , requires that Time Limited Aging Analyses (TLAA) that meet the six criteria in 10 CFR 54.3 must be evaluated for the Period of Extended Operation (PEO) and included in the license renewal application (LRA). TLAAs are analyses that involve systems, structures, and components within the scope of the license renewal rule, consider the effects of aging, involve time-limited assumptions defined by the term of the current operating license, and demonstrate that the analyzed aging effect will not adversely affect the capability of a structure or component to perform its intended function. The TLAA must be evaluated to show that the TLAA is valid through the PEO, can be projected to the end of the PEO, or the aging effect will be managed.

For analyses to be TLAAs, they must be part of the plant’s Current Licensing Basis (CLB) that show the parameter of concern will be acceptable through the current license period. They are not required to have been previously approved by the United States Nuclear Regulatory Commission (US NRC). Analyses that are for timeframes shorter than the current license period are not TLAAs.

Any plant-specific exemptions that have been granted by the US NRC under 10 CFR 50.12 that are in effect and based on TLAAs as defined in 10 CFR 54.3 must be identified, evaluated, and included in the LRA in order to justify the continuation of the exemption for the PEO.

Identification of TLAAs[edit]

TLAAs are calculations that are contained in the plant’s CLB and meet the six criteria as defined in 10 CFR 54.3. The potential TLAAs are identified by reviewing the plant documents that constitute the CLB. A list of the typical set of documents to be reviewed is below.

| Typical Set of Documents to be included in the search for TLAAs |

|---|

| FSAR or UFSAR |

| Technical Specifications and Bases |

| Design Requirements Documents |

| Design Basis Documents |

| NRC Safety Evaluation Reports |

| Docketed Licensing Correspondence |

| Applicable analyses and reports prepared by the Reactor Supplier, the Architect Engineer, and other engineering companies |

| Plant calculations |

| Plant-specifications |

| 10 CFR 50.12 Exemption Requests |

| ISI and Inspection Relief Requests |

| The Quality Assurance Plan |

| The Fire Protection Plan |

| Topical reports included by reference in the FSAR |

| Industry standards that are listed in the FSAR that contain a time based calculation |

| Code of record mentioned in the FSAR that includes calculations required by that code |

This process should include communication with personnel in the plant’s licensing department to ensure all documents that are part of the CLB are identified for review, as well as to check the generic TLAAs included in the Standard Review Plan (NUREG-1800 / NUREG-2192) or the IGALL database, and a list of example plant-specific TLAAs from other similar nuclear power plants.

Once the documents to be reviewed have been identified, a keyword search is performed using a combination of relevant keywords. Below is a sample of the keywords to be used, but it is not an exhaustive list. Therefore, it's important to review the list and determine if there are other applicable keywords for the plant. Once the keywords have been located in the documents, the information is carefully reviewed to determine if a calculation or analysis meets the six criteria of being a TLAA. All the reviews are documented as supporting documents for the LRA.

| Keyword Search Terms | |||

|---|---|---|---|

| 40 years, 40/year | Design life | IGSCC | Service life |

| Aging | Degradation | Leaching | Settlement |

| Analysis | Effective full power years (EFPY) | License / life | Thinning |

| Component life | Embrittlement | License term | Qualified life |

| Corrosion | Equipment / life | License period | Starts |

| Corrosion allowance | Erosion | Life / limit | Wear |

| Crack growth | Erosion allowance | Life of the plant | Years |

| Creep | Fatigue | Lifetime | |

| Cumulative usage / factor | Fatigue / analysis | Neutron fluence | |

| Cycle | Flaw size | Plant life | |

| Cycle / year | Forty years | Relaxation | |

| Depletion | Fracture toughness | SCC (Stress Corrosion Cracking) | |

Definition of a TLAA[edit]

The six specific criteria as defined in 10 CFR 54.3 for an analysis to be a TLAA are as follows. The words from 10 CFR 54.3 are shown in italics.

- Involve systems, structures, and components within the scope of license renewal as delineated in §54.4(a). The system, structure, and component scoping step of the integrated plant assessment (IPA) may be performed prior to or concurrent with the TLAA identification.

- Consider the effects of aging. The effects of aging include but are not limited to loss of material, loss of toughness, loss of prestress, settlement, cracking, and loss of dielectric properties.

- Involve time-limited assumptions defined by the current operating term, for example 40 years. The defined operating term should be explicit in the analysis. Simply asserting that a component is designed for a service life or plant life is not sufficient. The assertion should be supported by calculations or other analyses that explicitly include a time limit.

- Were determined to be relevant by the licensee in making a safety determination. Relevancy is a determination that the licensee must make based on a review of the information available. A calculation or analysis is relevant if it can be shown to have direct bearing on the action taken as a result of the analysis performed. Analyses are also relevant if they provide the basis for the licensee’s safety determination and, in the absence of the analyses, the licensee may have reached a different safety conclusion.

- Involve conclusions or provide the basis for conclusions related to the capability of the system, structure or component to perform its intended functions as delineated in §54.4(b). As stated in the first criterion, the intended functions may be identified prior to or concurrent with the TLAA identification. Analyses that do not affect the intended functions of the system, structure, or components are not TLAAs.

- Are contained or incorporated by reference in the current licensing basis. Plant-specific documents contained or incorporated by reference in the CLB include the Final Safety Analysis Report (FSAR), Safety Evaluation Report (SERs), Technical Specifications, the fire protection plan/hazards analyses, correspondence to and from the US NRC, Quality Assurance (QA) plan, topical reports included as reference to the FSAR, or correspondence to the US NRC (see tables in Generic TLAAs section). Calculations and analyses that are not in the CLB or not incorporated by reference are not TLAAs. When the code of record is mentioned in the FSAR, for particular groups of structures or components, referenced material includes all calculations required by that code of record for those structures and components.

Evaluation of a TLAA for License Renewal[edit]

10 CFR 54.21(c)(1) requires that the LRA include the TLAAs for the plant and the results of the evaluation as to how the TLAA will be addressed for the PEO. There are three ways to perform this evaluation as follows. The words from 10 CFR 54.21(c)(1) are in italics.

- Verify that the TLAA is valid for the PEO. In this approach, the original analysis is reviewed and it is determined that although the CLB only shows that the aging will be managed until the end of the original license, the analysis showed that the aging will be managed for a longer time period that extends through the PEO. This information is presented in the LRA, but a new analysis is not required.

- Justify that the TLAA can be projected to the end of the PEO. This can be done if the original analysis was only done to the end of the original license by extending the original analysis to the end of the PEO to show that the parameter will not exceed limits at the end of the PEO. In other cases, the analysis may be revised by reevaluating conservative conditions and assumptions or by using new or refined analytical techniques.

- Verify that the TLAA is resolved by managing the effects of aging. If the parameter of concern is a physical measurement, such as the thickness of a section of pipe that is experiencing loss of material, inspection of the component can be used to demonstrate that the component will maintain its intended function for the PEO.

- If none of the three options can be used successfully to evaluate the TLAA, the fourth option is to repair or replace the component and then manage the aging effect if it will still be occurring. For example, replacement of carbon steel piping that is subject to erosion with a stainless steel pipe that is not subject to erosion before the time the TLAA has been evaluated for may be the resolution of the TLAA. The replacement would be a license renewal commitment in the LRA.

IAEA International TLAA Approach[edit]

The International Atomic Energy Agency (IAEA) suggested approach to TLAAs is adopted by many Member States. This approach is very similar to the one described in this section with minor nuances. The main reference documents for the IAEA’s approach are the Safety Standards SRS-82 “International Generic Ageing Lessons Learned – IGALL” and SSG-48 “Ageing Management and Development of a Programme for Long Term Operation of Nuclear Power Plants”.

Once the TLAAs are identified, the experts must decide whether the analysis or calculation meets the criteria described in paragraph 5.64 of SSG-48. These criteria are very similar to the ones defined by the US NRC and listed in the “Definition of a TLAA” section with minor changes in wording. The main difference in SSG-48 is in paragraph 5.65 which states that “Safety analyses that meet all criteria except for criterion 6 of paragraph 5.64, and which have been developed in Member States to demonstrate preparedness for the intended period of operation, should also be considered as time limited ageing analyses.“ In other words, IAEA states that the analyses or calculations that meet the previous 5 criteria and are not contained or incorporated by reference in the CLB and at the same time were contemplated by other Member States for LTO, should also be considered TLAAs.

Contrary to plant-specific exemptions granted by the US NRC under 10 CFR 50.12, the International Generic Ageing Lessons Learned (IGALL) does not remark in an explicit way the consideration of an exemption as a potential TLAA. Even so, all plant exemptions must be verified against the criteria for a TLAA and if so, they should be considered a TLAA.

With regards to the revalidation methods for a TLAA to be valid for the intended period of operation, those suggested by IAEA in SSG-48 are also similar to those described in the “Evaluation of a TLAA for License Renewal” section. It is worth highlighting that the third revalidation method discussed in SSG-48 suggests that the management of aging effects is executed by a valid plant aging management program (AMP) (Section 5.67). The main advantage is that the AMPs have easy traceability and a period of execution, whereas a unique inspection of aging effects of a component might be insufficient in terms of long-term monitoring.

The list of the generic TLAAs is continuously updated and revised in the IGALL database.

Generic TLAAs[edit]

The two lists below are TLAAs from both SRP-LR and IGALL.

| List of generic TLAAs from SRP-LR (NUREG-1800 , Tables 4.1-2 and 4.1-3) |

|---|

| Reactor Vessel Neutron Embrittlement |

| Metal Fatigue |

| Environmental Qualification of Electrical Equipment |

| Concrete Containment Tendon Prestress |

| Inservice Local Metal Containment Corrosion Analyses |

| Intergranular Separation in the Heat-Affected Zone (HAZ) of Reactor Vessel Low-Alloy Steel Under Austenitic Stainless Steel Cladding |

| Low-Temperature Overpressure Protection (LTOP) Analyses Fatigue Analysis for the Main Steam Supply Lines to the Turbine Driven Auxiliary Feedwater Pumps |

| Fatigue Analysis for the Reactor Coolant Pump Flywheel |

| Flow-Induced Vibration Endurance Limit for the Reactor Vessel Internals |

| Transient Cycle Count Assumptions for the Reactor Vessel Internals |

| Ductility Reduction of Fracture Toughness for the Reactor Vessel Internals |

| Leak-Before-Break |

| Fatigue Analysis for the Containment Liner Plate |

| Containment Penetration Pressurization Cycles |

| Metal Corrosion Allowance |

| High-Energy Line-Break Postulation Based on Fatigue Critical Usage Factor (CUF) |

| Inservice Flaw Growth Analysis that Demonstrates Structure Stability for 40 years |

Plant-specific TLAAs[edit]

Apart from the generic TLAAs, nuclear power plants must also ensure that all plant- specific TLAAs are considered before entering into LTO. Plant-specific TLAAs are based on the peculiarities of each power plant, and they may be applicable only to one NPP. Therefore, during the TLAA identification stage, an extra effort is dedicated to identify them.

Plant-specific TLAAs are revalidated with the same revalidation methods as described in the “Evaluation of a TLAA for License Renewal” section.

| Examples of plant-specific TLAAs (See US Plant LRAs for more information) |

|---|

| Reactor Building Crane Cyclic Loading Analyses |

| Turbine Building Crane Cyclic Loading Analyses |

| Reactor Shield Wall Fluence |

| Fuel Pool Storage Rack Fatigue Analysis |

| Main Steam Line Flow Restrictors Erosion Analysis |

| Inservice Flaw Growth Analyses that Demonstrate Structure Stability for 40 Years |

Examples of TLAA Evaluations using 10 CFR 54.21(c)(1)[edit]

These are examples of TLAAs that were in license renewal applications and have been accepted by the US NRC. While the plant specific names have been omitted, specific references to industry standards and other publicly available information has been retained. These examples include the three approaches in 10 CFR 54.21(c)(1) to disposition the TLAAs.

10 CFR 54.21 (c)(1)(i) – Example

10 CFR 54.21 (c)(1)(ii) – Example

10 CFR 54.21 (c)(1)(iii) – Example

References[edit]

- Specific Safety Guide No. SSG-48, “Ageing Management and Development of a Programme for Long Term Operation of Nuclear Power Plants.” International Atomic Energy Agency. November 2018.

- IAEA 2024, IGALL Documents website, accessed 13 March 2024,

- US NRC Standard Review Plan NUREG-1800 Rev. 2

- NEI 95-10 Rev. 6 Industry Guideline For Implementing The Requirements of 10 CFR 54 – The License Renewal Rule

Record of Revisions[edit]

| Number | Date | Description of Changes |

|---|---|---|

| 0 | 6/11/2024 | Initial version |